Firestopping is a critical component of passive fire protection in buildings. It refers to the process of sealing openings and joints in fire-rated walls or floors to prevent the spread of fire, smoke, and toxic gases.

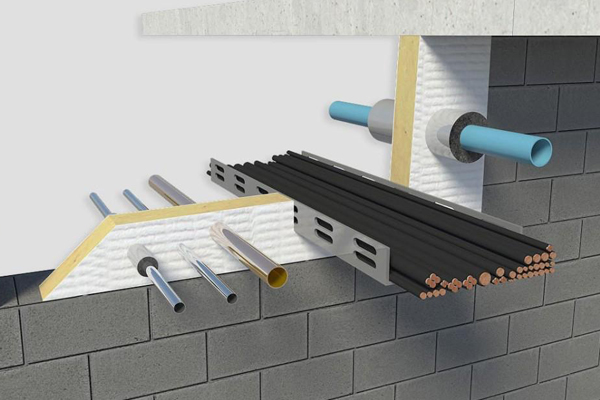

Buildings often have pipes, cables, ducts, or other services that penetrate fire-rated walls and floors. These penetrations create potential pathways for fire to spread. Firestopping restores the integrity of fire-rated barriers.

Intumescent sealants: Expand when exposed to heat, sealing gaps.

Firestop collars and wraps: Used around pipes.

Fire-rated mortar or putty: Used to fill larger openings.

Firestop pillows or blocks: Used in temporary or frequently accessed penetrations.

Fireproofing is the process of making materials or structures resistant to fire, or slowing down the spread of fire. It’s commonly used in buildings, industrial facilities, and infrastructure to protect lives, property, and equipment.

Fireproofing : Involves applying fire-resistant materials (like sprays, boards, or coatings) to structures such as steel beams, walls, or ceilings. These materials don’t actively fight fire but provide thermal insulation to delay structural failure.

Waterproofing is the process of making a surface or structure resistant to the penetration of water. It is commonly used in construction to protect buildings and infrastructure from water damage, mold, and corrosion.

Roofs – To prevent rainwater from leaking into the building.

Basements – To stop groundwater from seeping through walls or floors.

Bathrooms and Kitchens – To keep moisture from damaging tiles, floors, and walls.

Foundations – To protect the structural integrity of the building.

Tanks, pools, and terraces – To retain water without leakage.